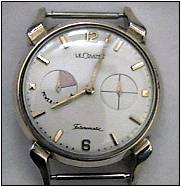

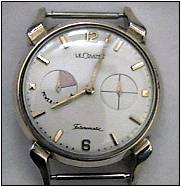

Eugenio was posting an image of a wonderful Jaeger-LeCoultre Futurematic on Timezone. It is a bumper automatic watch from the 1950s, that features no winding crown, or more precisely, it has a crown hidden on the back of the watch.

Here is some information on this watch, and explanations of its interesting mechanisms.

I would like to thank Walt Odets and Eugenio for helping me improve this article. Apologies for my crude use of "watch terms". All errors are mine (of course!).

-matwat�

Jaeger-LeCoultre Futurematic

�

� Image 1 - Two examples of Calibre 497

Image 1 - Two examples of Calibre 497

Image 2 - Calibre 817

The Jaeger-LeCoultre catalogue refers to the Futurematic model: "The remarkable Calibre 497 automatic movement needed no winding crown in the Futurematic watch of 1953."

Image 2 - Calibre 817

The Jaeger-LeCoultre catalogue refers to the Futurematic model: "The remarkable Calibre 497 automatic movement needed no winding crown in the Futurematic watch of 1953."

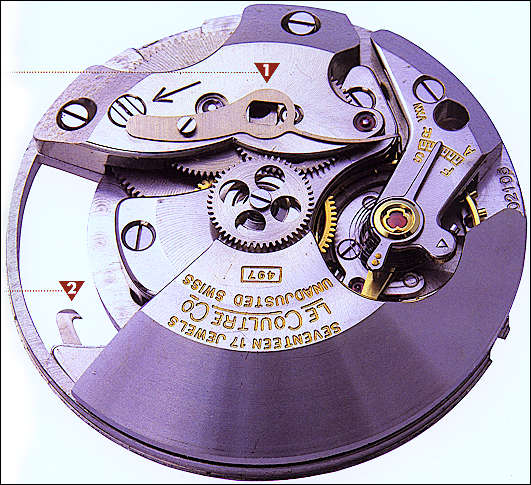

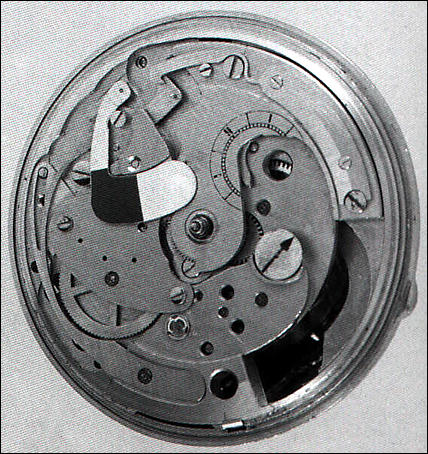

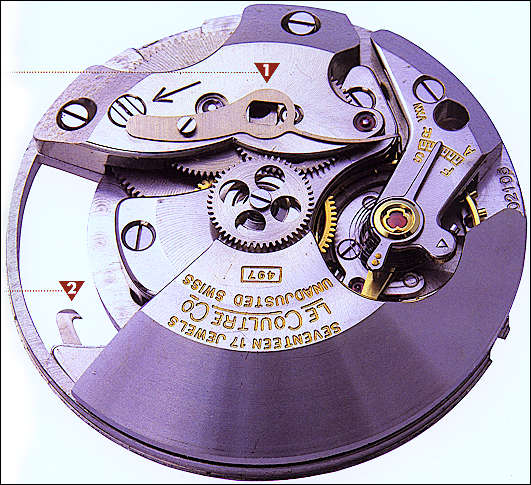

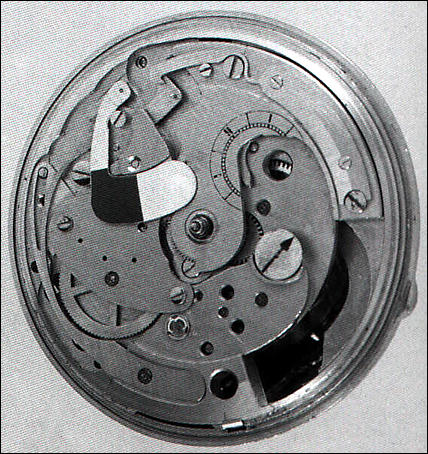

Jaeger-LeCoultre actually produced two calibres that were used in the Futurematic.� The first was the 497 which was a 17 jewelled bumper automatic featuring a sub-dial with a hand to display the power reserve (Image 1).� The next calibre was the 817 which was virtually the same movement except that it used a coloured port-hole to display the state-of-wind of the watch (Image 2).

Movement Details

Diameter - 31.3 mm (13 3/4")

Height - 6.3 mm

17 jewels

Balance - Two spoke Glucydur, with adjustment screws

Balance Spring - Nivarox spiral

Frequency - 18,000 A/hr, 2 Hz

Kif shock absorbing

Image 3 - View of top/front of 497 movement

Click image for huge enlargement (236k)

Image 3 - View of top/front of 497 movement

Click image for huge enlargement (236k)

This is a bumper automatic movement. You can see the bumper/rotor occupying the lower third of Image 3 (it is inscribed with SEVENTEEN 17 JEWELS... etc.). On the left-hand end of the rotor is a hook (Red Triangle 2) which is part of the overwind prevention mechanism (see section 2).

At the top-centre of the movement is a four-holed wheel which is for adjusting the hands (see section 3). The toothed wheel below the four-holed wheel is the centre wheel. To the left of that, you can see the mainspring barrel (the lowest of all five visible wheels), which is also visible at 11:30. The two wheels above the four-holed wheel and to the right of the barrel are winding reduction wheels. The transfer wheel from the rotor is below the centre wheel, driving the pinion of the first of the two wheels above the four-holed wheel. The third, fourth, and escape wheels are hidden beneath the rotor (at the six to four o'clock positions).� At Red Triangle 1 is the hack lever (see section 3).

�

�

Image 4 - View of back (dial side) of 817 movement

In Image 4 the bumper is located in the top right third.� The overwind hook is attached to this side of the bumper, and can be seen at 12 o'clock.� To the right of the centre of the movement is a small disk with an arrow for displaying the seconds in a sub-dial/port-hole. To the left of centre is the power reserve display tab (bi-coloured dog's-leg).

Image 4 - View of back (dial side) of 817 movement

In Image 4 the bumper is located in the top right third.� The overwind hook is attached to this side of the bumper, and can be seen at 12 o'clock.� To the right of the centre of the movement is a small disk with an arrow for displaying the seconds in a sub-dial/port-hole. To the left of centre is the power reserve display tab (bi-coloured dog's-leg).

1. Power Reserve�

��

�� �

�

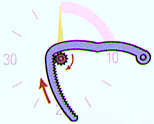

Image 5 - cal.497

Image 5 is from the dial side (back of the movement) of the 497.� As the mainspring is wound, the reserve mechanism drives the small wheel clockwise, turning the hand (on the wheel's pivot) clockwise to display the power reserve.� The hooked ratchet arm is also driven by the small wheel, and rotates clockwise as the mainspring power reserve increases.

In the 817 there is no pivot extension on the small wheel, in its place there is the bi-coloured tab attached over the hooked ratchet arm (Image 4), this tab is visible through a port-hole in the dial.� So as the hooked ratchet arm moves, the port-hole reveals the dark colour when the watch requires winding, and the light colour when the watch is fully wound.

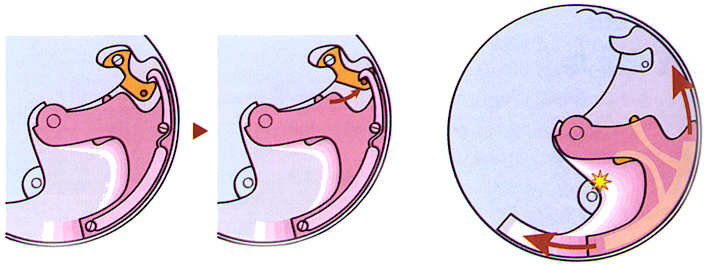

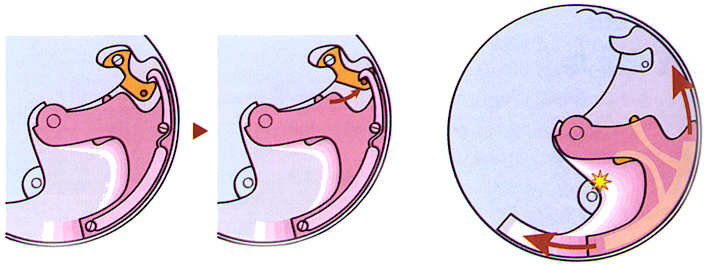

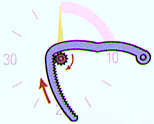

2. Bumper & Overwind Protection�

This is another image from the back of the movement, just to the right of the power reserve mechanism (Image 5).� It is shows the hook which is attached to the edge of the bumper/rotor, and you can also see a lever with a pin to the left of the hook.

This is another image from the back of the movement, just to the right of the power reserve mechanism (Image 5).� It is shows the hook which is attached to the edge of the bumper/rotor, and you can also see a lever with a pin to the left of the hook.

�

This series of illustrations shows the movement of the bumper/rotor.� The hammer shaped rotor swings through an arc of about 90 degrees, and winds the mainspring in both directions.� The middle diagram shows the hook on the bumper (red-pink) latching onto the pin on the lever (orange).� This is the overwind protection.� As the power reserve ratchet arm moves clockwise (Image 5), it allows the lever with the pin to gradually move anti-clockwise and outwards... so it catches the bumper hook when the watch reaches a fully-wound state -- preventing movement of the bumper.� In the far right illustration is a peach coloured arc with two blade spring "antennae" which provide "shock adsorption" for the bumper (other bumpers that I have seen use springs mounted on the movement to adsorb the shock of the bumper's motion).

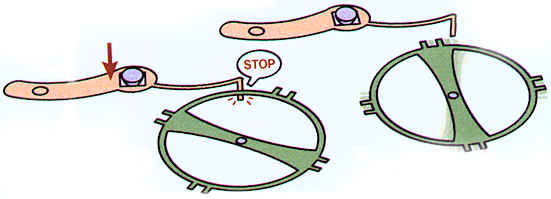

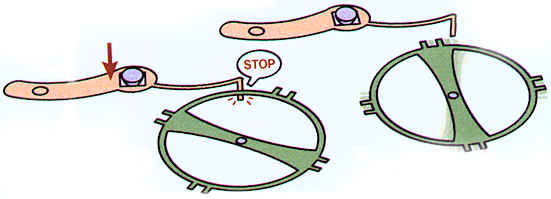

3. Crown & Hack�

The watch "needs no winding crown", but as you can see... there is a crown shaped like a coin on the back of the watch.� The crown is inscribed with SLIDE - DO NOT LIFT.� On the inside of the back is a toothed wheel... this wheel can be engaged with the four-holed wheel at the centre-top of the movement (see Image 3) - enabling adjustment of the hands. A small knob also protrudes from the centre of the wheel in the back of the watch. This small knob fits into the slot/hole in the centre of the hack lever (Image 3, Red Triangle 1).

The watch "needs no winding crown", but as you can see... there is a crown shaped like a coin on the back of the watch.� The crown is inscribed with SLIDE - DO NOT LIFT.� On the inside of the back is a toothed wheel... this wheel can be engaged with the four-holed wheel at the centre-top of the movement (see Image 3) - enabling adjustment of the hands. A small knob also protrudes from the centre of the wheel in the back of the watch. This small knob fits into the slot/hole in the centre of the hack lever (Image 3, Red Triangle 1).

This illustration shows how the hack system works.� To adjust the time the crown is slid towards the centre of the watch, this moves the hack lever (rotating it clockwise) to contact with the balance, stopping the movement. That action also engages the toothed wheel in the back of the watch with the four-holed wheel at the top-centre of the movement enabling time adjustment by rotation of the crown.

This illustration shows how the hack system works.� To adjust the time the crown is slid towards the centre of the watch, this moves the hack lever (rotating it clockwise) to contact with the balance, stopping the movement. That action also engages the toothed wheel in the back of the watch with the four-holed wheel at the top-centre of the movement enabling time adjustment by rotation of the crown.

References�

Numerous images and diagrams are taken from WORLD WRIST WATCH TIME SPEC Issue 35 (Cartier Tank on cover). Pages 162-163.� Photos by Tomoaki Tsuruda(WPP), Illustration by Ken Mashida(JI).� Copyright by WORLD PHOTO PRESS Printed in Japan.� ISBN4-8465-2163-X.

Numerous images and diagrams are taken from WORLD WRIST WATCH TIME SPEC Issue 35 (Cartier Tank on cover). Pages 162-163.� Photos by Tomoaki Tsuruda(WPP), Illustration by Ken Mashida(JI).� Copyright by WORLD PHOTO PRESS Printed in Japan.� ISBN4-8465-2163-X.

Klassik Uhren

"Armbanduhren aus der Schweiz" by Heinz Hampel. Printed by Cailway Verlag M�nchen.

Addendum�

After writing this article I received an E-mail from James Dowling...

-----------------------------------------------------------------------

Hi Matwat;

Nice piece on the FM; it has one other little tweak that you missed.

When the watch is not being worn the mainspring will NOT run all the way down;

the stopwork will engage when there is about 6 hours of power reserve left.

This means that as soon as the watch is picked up, the stopwork disengages and

the watch will start immediately.

Two other points

1 The watch is the only watch other than the Harwood where the rotor is

suspended both above and below the movement. This gives support on both sides

of the rotor and means there is no possibility of lateral movement. A major

problem with almost all automatics.

2 Because of the hook which stops the winding rotor when the mainspring is

fully wound there is therefore no need for a slipping cliutch on the

mainspring (as used on all other autos) a possible cause for error.

In closing I have heard from ex Jaeger people who were there in the 50s that

the company lost major amounts of money on every watch they sold as it was

massively overcomplex and over engineered.

Thanks & good luck

James

-----------------------------------------------------------------------

Thank you for the very interesting information James. I hope you don't mind me putting your message on my homepage.

Here are some additional pictures of futurematics from the web...

mailto:[email protected]

mailto:[email protected]

�

�

�

�

��

�� �

�