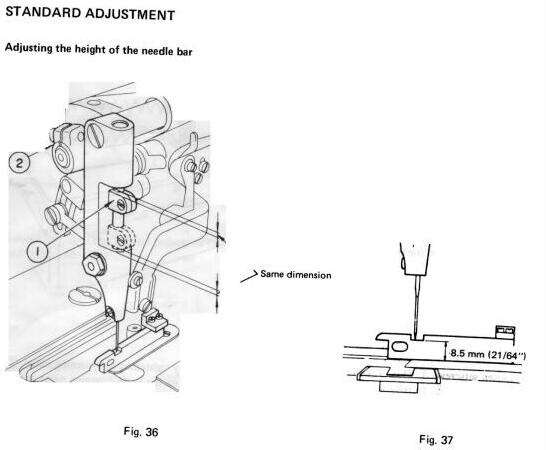

The standard needle bar height is 8.5mm (21\64 in) clearance between

the needle point and the surface of the throat plate when it has risen

to it's full height.

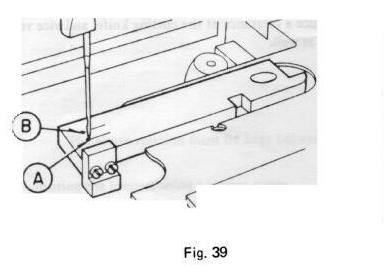

To adjust loosen screw (1) (Fig 36) in the needle bar clamp, place

timing gauge in the way shown in (Fig 37) adjust the height of the needle

bar and firmly tighten the screw.

Never adjust the needle bar height by screw (2)

(Fig 36) without loosening screw (1) of the needle bar clamp in any circumstances,

because it will change the trajectory of the needle bar motion.

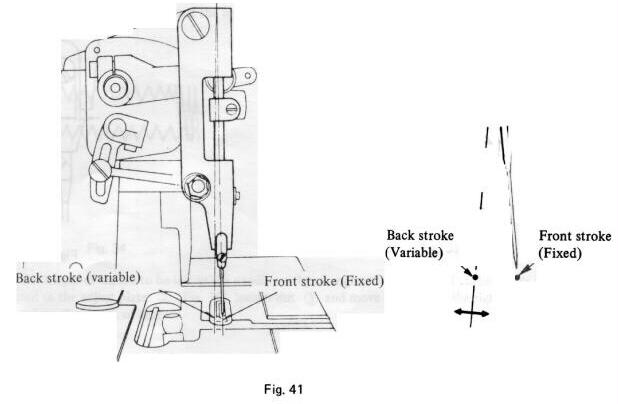

Adjusting the rocking motion of needle bar