Introduction To Curveline

|

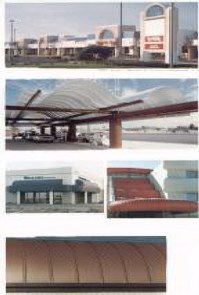

Curveline, Inc. specializes in custom-curved profiled metal panels. With their versatile "crimp-curving" process-so unique it's patented in 14 countries-you can now design a wider range of contours and shapes, using a wider selection of panel profiles, than ever before available.

|

A wide variety of profiled panels can be crimp-curved by Curveline, as follows:

Panel thickness:.016" to .049"

(18 gauge to 26 gauge)

Panel length: 2 ft. to 30 ft.

Panel depth: 3/4" to 6"

Panel width: 5 ft Maximum

Internal radius: 10" minimum

Angle: 0 to 180 degrees

Length of Bend:

B-(R + H ) x 3.14 x 0

180

Straight Lengths:

S1 or S2 + b + S2

Recommended tensile strength:

50,000 psi

Materials: Panel materials suitable for crimp-curving include painted or unpainted galvanized steel, aluminum, aluminized steel or stainless steel. The most favorable steel composition for curving is ASTM A 446 Grade D Carbon Steel G-90; Yield 50,000 PSI. It is also possible to curve perforated or smooth panels.

Panel Finishes:

Standard panel finishes include silicone polyesters; Corrstan multi-mil protective coatings; Kynar 500 fluorocarbon resin based coatings (e.g. Glidden Nubelar and PPG Duranar; and Dextar 850 fluorocarbon coatings. Crimp-curving can also be performed on panels which are pre-primed and post-painted in any desired color.

Panel Profiles: As long as the desired panel is within the above guidelines, Curveline can form it into shape using the appropriate dies for each different panel.

Limitations:

Minimum radius is in general 10", depending on panel depth.

Minimum panel length is 2 ft.

High tensile Galvalume steel sheeting can be subject to brittleness.

Warranty: Warranty on materials and finishes are given by the panel manufactures. Curveline, Inc. warrants the fabrication process and the order specification. No implied or express warranty for fitness or purpose is made.