INJECTOR

CONTROL

The computer activates the fuel injector(s)

to control fuelmetering by varying the injector driver's pulse width and

frequency.The pulse width and frequency is a function of the computer sensed

inputs as defined by the system application.

Two modes of active

control are possible:

open loop and,

closed loop.

Using information from the oxygen sensor.

The mode control is determined by the computer's ability to measure the

exhaust oxygen content. If the exhaust oxygen content cannot be measured,

the computer controls fuel injection in the open loop mode. In the closed

loop mode when a rich air/fuel ratio is detected, the injector control

duty cycle is decreased to cause a leaner air/fuel mixture, and vice versa

for a lean air/fuel ratio.

If the computer malfunctions,

fuel control is performed in the open loop mode by the Backup fuel circuitry

within the PCM (see Backup fuel Control).The

PCP flag for paragraph 3.3.6 identifies an

emissions related function and applies over the temperature range of 0

c to 40 c and a battery voltage of 11 to 16 V.

The ability of the

injector outputs to turn on and off meeting the pulse width accuracy should

be verified (see computer control)

The PCP flag also identifies a safety related

feature of back-up fuel.The ability of back-up injector control should

be verified (see Backup fuel Control).The

two low side fuel injector drivers may be operated in the following modes

(base PCM P/N 16127470).The base model operates in the ramp and hold mode.

|

MODE

|

|

Notes

|

|

1

|

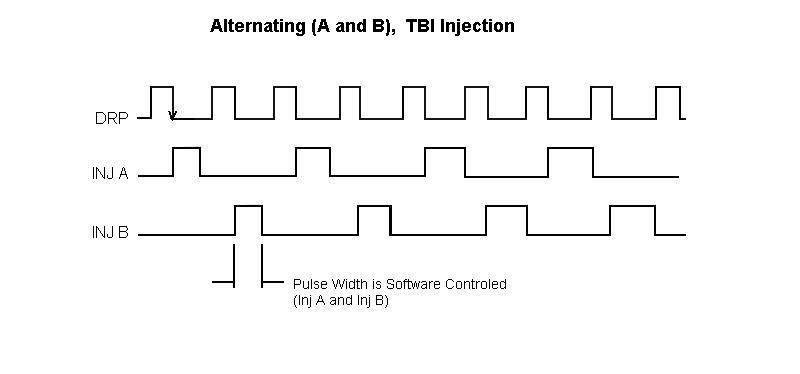

Alternating TBI

|

Both injectors used

|

|

2

|

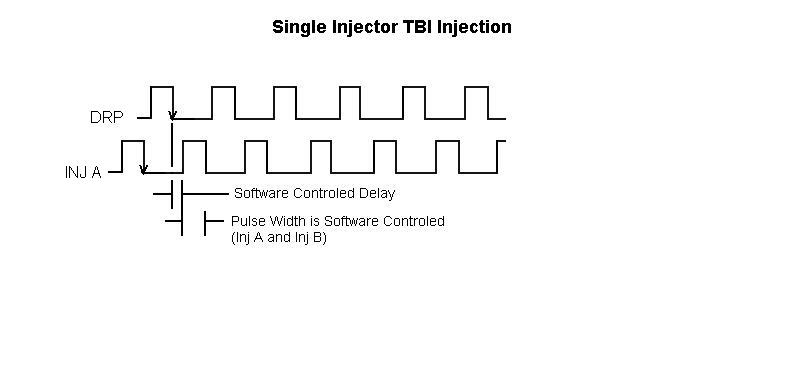

Single Injector TBI

|

2nd injector driver not connected

|

Alternate base models can be derived which

provide these additional fuel modes.These applications would require Hi-impedance

injectors to run ramp and hold, on the removal of the 0.1 ohm current sample

resistor and replacing it with a zero Ohm jumper (R194 and R199) to operate

in the saturated mode.

|

MODE

|

|

Notes

|

|

3

|

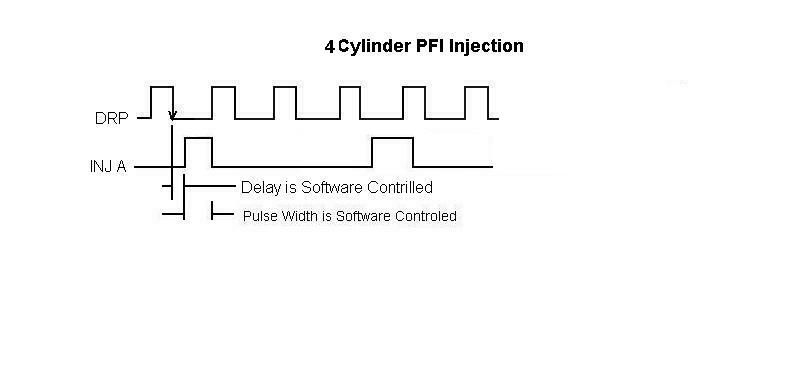

4 Cyl PFI

|

|

|

4

|

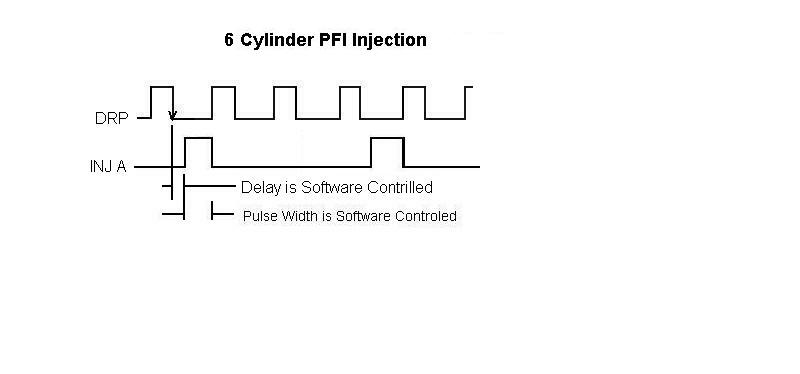

6 Cyl PFI

|

|

|

5

|

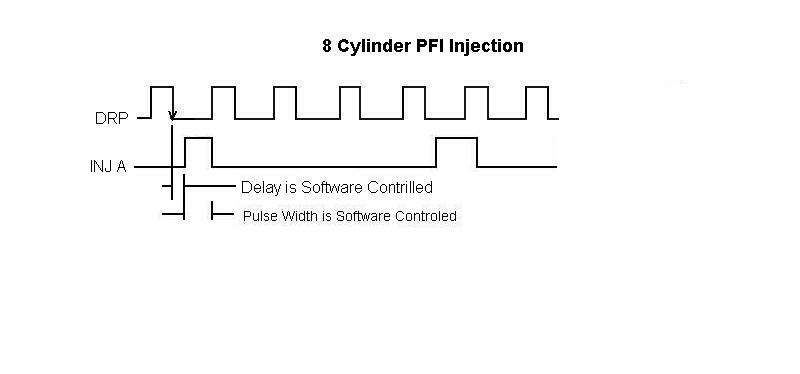

8 Cyl PFI

|

|

Modes 1 through 5 are for ECU controlled fuel pulses

PFI/TBI

MODE SELECTION

To set the PFI/TBI

modes just described, the MEM/CAL assembly resistors R29 and R30 must be

set to proper values. These two resistors form a voltage divider network

between a 5 volt line, VRFD, and ground which enables decoding the REFHI

input signal according to the mode selected.

The divided input voltage level and its

relationship to the injector operating mode is shown in the table below,

MEM/CAL Mode Selection.

The mode selected also has a critical relationship

to ignition spark events, EST output, as described in Ignition, Spark and

Dwell Control.

|

MEM/CAL

Mode Selection |

|

| Application |

Mode Input Voltage(R29/R30 ratio) |

Frequency Of Injection |

| 1. Alternating TBI |

2/3 VRFD + 10% |

ALT. Every REF pulse |

| 2. Single Injector TBI |

VRFD + 0% - 10% |

Every REF pulse |

| 3. 4 Cyl. PFI |

2/3 VRFD +/- 10% |

Every 4th REF pulse |

| 4. 6 Cyl. PFI |

1/3 VRFD + 10% |

Every 3rd REF pulse |

| 5. 8 Cyl. PFI |

GND -0% + 10% (5v) |

Every 4th rd REF pulse |

Note:

Applications

3 thru 5 require alternate base models to operate in The saturated drive

mode. Only peak & hold modes are permitted with this base model.

|

Computer

Control

Injector fuel pulses, under software control,

can occur synchronous or asynchronous to the DRP (distributor reference

pulses). Synchronous operation occurs during vehicle steady state conditions

while asynchronous operation occurs during transient conditions such as

acceleration, certain start up. conditions and coast down conditions.In

synchronous operation sane of the modes allow the start of injection to

be delayed frat the REF pulse as-a function of software.PCP flag requires

verification of pulse width accuracy over 00C to 400C,

battery voltage 11 to 16 V.

The

following pulse width and pulse delay accuracies apply over the normal

Computer voltage range (6.3 to 16 V) and the operating temperature range

(-40 C to 850C).

|

Injector

pulse width/Delay Accuracies (Computer Controlled)

|

|

Synchronous

Operation

|

Limits

|

|

A

|

Pulse

width range

|

0

to 499.98 usec

|

|

|

Computed

accuracy

(for

1 Count = 15.26 usec)

|

+2,

-1 Count

|

|

|

Computed

width

plus

driver switching delays

|

+58

to -15 usec

|

|

|

|

|

|

B

|

Pulse

delay range:

|

0

to 499.98 usec

|

|

|

Computed

accuracy:

(For

1 Count = 15.26 usec)

|

+2,

-1 Count

|

|

|

Computed

delay

Plus

driver on delay

|

+58

to -15 usec

|

|

|

Added

delay*

(REFA

to ECU)

|

93

to 73 usec

|

|

|

|

Asynchronous

Operation

|

Limits

|

|

|

Pulse

width

|

0

to 499.98 usec

|

|

|

Computed

accuracy

(for

1 Count = 15.26 usec)

|

+2,

-1 Count

|

|

|

Computed

width

plus

driver switching delays

|

+58

to -15 usec

|

NOTE:

A

time delay from the fall of REF A input signal to the Ear results from

RC filtering and circuit switching times. Time delay indicated results

at REFA equal to 5V (VOH)

|

Fuel

Control During Crank

Fuel injector pulses occur during engine

cranking conditions under computer control or backup control. Computer

control is the primary mode of operation. Backup control can take place

when the battery voltage falls below 6.3 V or will occur when the computer

software malfunctions.

Backup

Fuel Control

The PCM provides backup i njector control

upon detection of a digital processing failure (see computer operational

tests), or when the battery voltage falls below 6.3 VDC Injector

pulses occur synchronously to the REF distributor pulses. Fuel pulse width

is a function of coolant temperature, load input (MAP or TPS), ignition

voltage and crank or run engine speeds. Key function/features include the

following.

-

Fuel pulse width during crank or run conditions

-

Battery voltage/fuel pump compensation

-

Crank/run selection

-

Crank enleanment

-

Add-on timer

-

Clear flood

-

Outputs disabled

Outputs Inhibited

During Backup Fuel

During Backup fuel mode all outputs are

disabled except as noted here. The

outputs active are:

-

Fuel Injectors

-

Fuel Pump Relay

-

Check Engine Lamp

-

Check Transmission Lamp

Pulse

width Calibration

Backup calibration is contained in the

MEM/CAL assembly in the form of thirty resistors in two resistor networks.

To determine resistor values refer to TSO CT MANUAL $RFDCAL procedure.

Table

17 provides a typical set of calibration resistor values and Table

18 provides pulse widths at selected conditions for these values.

The pulse widths are presented as reference and verify back up performance.

These values do not necessarily represent a production set of calibration

values.

Pulse

width Accuracy

Pulse width measurements compared to calculated

pulse widths of $RFDCAL.

4.5V

to 16 V, -400c to 850C.

Pulse width accuracy: + 15%

Resistors

Forming Injector Pulse width

The basic pulse width is established by

the resistors R1 through R14 within the NEM/CAL networks.

In the crank mode, the pulse width is a function

of coolant temperature. Network resistors R1 through R5 provide the proper

curve shaping calibration and R6 provides the scaling calibration. In the

run mode, R7 provides scaling calibration and R8 provides additional scaling

calibration. Scaling between run and crank are independent and are a function

of r6 and R7 respectively.

Load

Shaping and scaling During

the run mode resistors Rl3 and R14 establish the base pulse width. Resistors

R9, R10 and R11 provide shaping while R12 provides scaling functions that

act to modify the base pulse width.

Battery

Voltage/Fuel Pump Compensation

This function provides

compensation for lower fuel pressure due to decreasing battery voltage

driving the fuel pump. It increases the injector pulse width as the ignition

voltage, law, decreases. The base pulse width is multiplied lx, l.5x or

2X depending upon the selection of resistor values R22, R23 and R24 and

IGNN voltage. Ignition voltage, lGNN, is the voltage source for the series

string R22, R23 and R24. As IGNN decreases the voltage nodes formed by

the resistors decrease in reference to the regulated 5V line, VRFD. Multiplier

1x is enabled when the voltage nodes of both R23-R24 and R22-R23 are above

1/3 VRFD. Multiplier 1.5x is enabled when voltage node of fl3-~4 is below

1/3 VRFD and voltage node PU2-R23 is above VRFD. Multiplier 2x is enabled

when both voltage nodes are below 1/3 VRFD. Fuel pump compensation is eliminated

by making R24 equal to 1 meg ohm.

Run/Crank

Selection

The determination of

run or crank conditions is accomplished by monitoring the engine speed

via the REF distributor input signal. Resistor R21 and a 0.1 ufd capacitor

form a one-shot oscillator, along with a counter, provides a time base

comparison to engine speed. RFDCAL computes the value of R21i for requested

crank or run engine speeds. The hystersis or difference between crank to

run engine speed and run to crank engine speed is a multiple of 4.

Crank Enleanment

This feature provides leaning out the

fuel after five engine revolutions have occurred. For each revolution following

the fifth revolution the pulse width is decremented by art; amount set

by resistor R16 (R18 must be open). The pulse width can be decremented

up to 31 times depending upon the coolant calibration temperature and calibration

values. Above or below this temperature

the minimum pulse is ratiometric to the crank calibration curve. The clamp

at the voltage node formed by Rl5 and a 10 K ohm pull up controls the minimum

pulse width. The voltage at this node must be.set:to100 mv or greater.

To prevent crank enleanment R16 must be open and R18 must be set to 10

K ohm.

Add-on-Timer

The add-on timer is typically used on

PFI applications to modify injector pulse widths to compensate for changing

injector opening times resulting from changes in battery voltages. The

add-on timer occurs before the fuel pulse is initiated. Resistors R17 and

R19 in-conjunction with R20 and IGNN voltage control this feature.

Clear

FloodThe clear flood function inhibits fuel pulses when the

throttle position opening exceeds 60% during the crank mode. The switch

point is set to 60% of VRFD with a tolerance of +/-10%.

Table

17

$RFDCAL Backup

Fuel That Calibration

(Typical values

in Ohm)

| Ref

Des |

Value |

|

Ref

Des |

Value |

|

Ref

Des |

Value |

| R1 |

147.0K |

|

R11 |

22.1K |

|

R21 |

383.0K |

| R2 |

11.3K |

|

R12 |

237.0K |

|

R22 |

25.5K |

| R3 |

34.0K |

|

R13 |

511.0K |

|

R23 |

681 |

| R4 |

14.3K |

|

R14 |

73.2K |

|

R24 |

5.49K |

| R5 |

2.1

MEG |

|

R15 |

Short |

|

R25 |

16.5K |

| R6 |

23.2K |

|

R16 |

Open |

|

R26 |

24.9K |

| R7 |

10.0K |

|

R17 |

154.0K |

|

R27 |

Short |

| R8 |

75.0K |

|

R18 |

10.0K |

|

R28 |

OPEN |

| R9 |

80.6K |

|

R19 |

3.09K |

|

R29 |

20K |

| R10 |

536.0K |

|

R20 |

15.8K |

|

R30 |

10K |

|

Table

18

$RFDCAL Test

Pulse Widths, 250c

Battery voltage = 12 volts, 4K pull up. $RFDCAL

values.

Coolant = Deg c

MAP = Kpa

Pulse width in msec.

| Coolant

Temp |

Crank

MAP=100 |

Run

MAP=50 |

MAP

Press. |

Run

Cool+20 |

Run

Cool+90 |

| -20 |

74.5 |

10.3 |

100 |

11.3 |

7.9 |

| -10 |

48.1 |

8.9 |

90 |

10.1 |

7.1 |

| 0 |

8.9 |

7.6 |

80 |

9.0 |

6.3 |

| 10 |

23.9 |

6.4 |

70 |

7.8 |

5.5 |

| 20 |

18.7 |

5.6 |

60 |

6.7 |

4.7 |

| 30 |

15.6 |

5.0 |

50 |

5.6 |

4.0 |

| 40 |

13.7 |

4.6 |

40 |

4.5 |

3.2 |

| 50 |

11.5 |

4.3 |

|

|

|

| 60 |

11.8 |

4.1 |

|

|

|

| 70 |

11.3 |

4.0 |

|

|

|

| 80 |

11.1 |

4.0 |

|

|

|

|

TBI

INJECTOR DRIVER CHARACTERISTICS

TBI Applications

In TBI applications, the drivers operate

in the peak and hold (1 A) mode provided the battery voltage is sufficient

to reach the peak (4 A) condition. The

injector loads, A and B, are connected from switched battery to injector

driver outputs INJA/ and TNJB/ respectively. NEM/CAL

mode select (R29/R30) must be hardware programmed for TBI applications

as described in, Table 18. Also, software

must command the PMID via an internal signal (M/CLR), to control injector

current in the peak and hold node. N/CLR must be a logic zero for this

application. As noted, specific applications may delete one driver if required.

TBI Output Current

Profiles

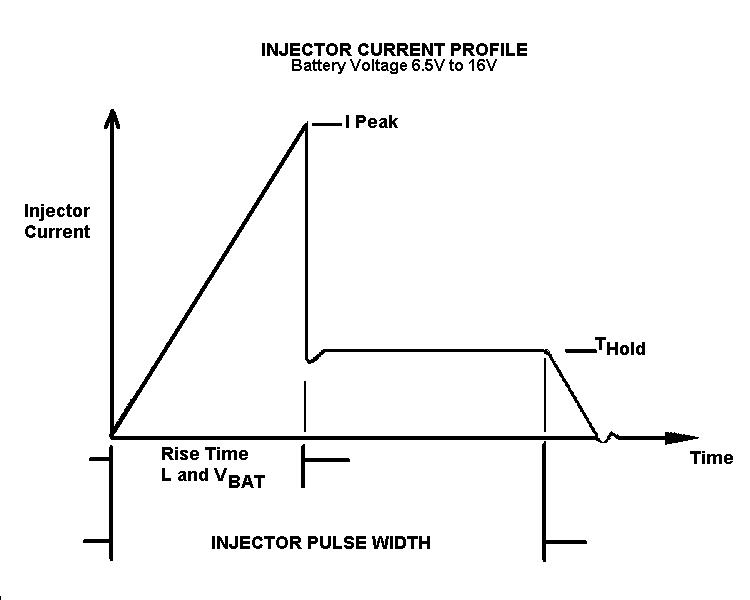

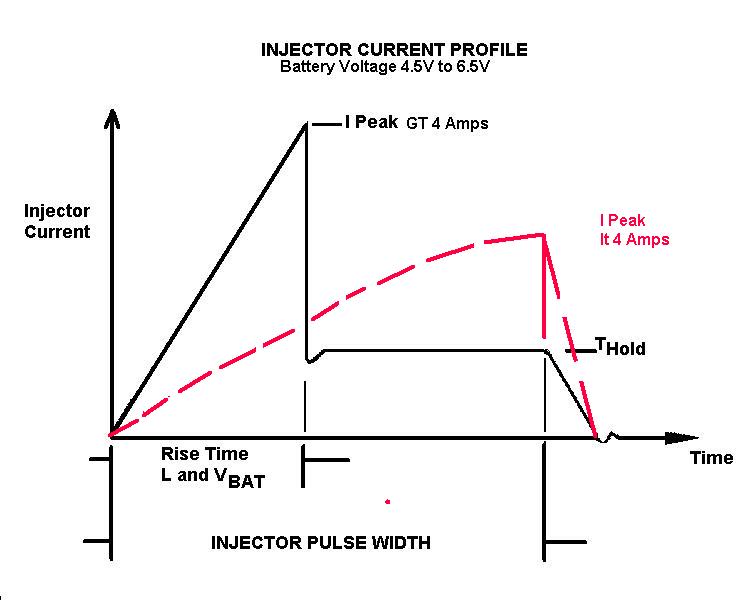

Injector current profiles are shown in

Figures 2 and 3. The current rise time will vary as a function of injector

solenoid inductance and resistance, the battery voltage and to a lesser

degree the driver saturation voltage which varies with temperature.

The driver operates in the saturated mode until the 4 A peak is sensed

and then regulates to 1 A during the hold mode as shown in Figure 3. Decreasing

the injector resistance will permit the peak current to be realized at

a lesser voltage than shown in Figure 3, which illustrates the current

wave shape for

an injector resistance equal to 1.0 ohm. It

must be-noted, Figures 2 and 3 reference 6.5 V as the voltage threshold

below which the peak current may not- be realized. This assumes no external

voltage drops occur relating to the injector wire harness and the PCM ground

harness. In practice, and testing, this minimum value is not universal,

and should be evaluated using the "TB! Output Voltage" section, which identifies

driver performance.

TBI Output Voltages

The output voltage from the injector driver(S),

signals INJA/ and INJB/, during the saturated portion of the peak and hold

mode is expressed below as VOUT/ Were:RPCM

= (RDSON + RCKT.BD +RCONT.CONT + RSAMPLE)

RH = Resistance of external injector

harness and PCM Ground harness.

RINJ

=

Resistance of injector load

The PCM's saturated mode on resistance (RPCM)

during activation time is tabulated below.

Table 19

Maximum Peak

and Hold Saturation Resistance * (Ohms)

For VBAT = 4 5 to 16V

IINJ eq or lt 5Amp (reference

value)

| Temperature |

-40c

|

25c

|

85c

|

| RPCM(MAX)

Ohm |

0.45

|

0.50

|

0.65

|

|

The minimum battery voltage required to

achieve the 4Amp peak condition can be calculated in general from the following:VBAT

(min = 4 Amp (RH

+ RINJ + RPCM)Note:The

4 Amp condition is the typical value, not worst case.

Injector Clamping

The injector driver clamp limits the voltage-across

the driver to protect it and to ensure a fast injector turn off. he clamp

circuit utilizes the driver as a power zener in this mode. Clamp voltages

tabulated below are for battery voltages of 6.3 to 24.5V. A minimum clamp

voltage of 49V can result when the~ battery voltage is less than 6.3 V.Injector

Clamp Voltage = 86 +/- 14V (6.3V lt. VBAT 24.5 V)

|

Current

Performance Accuracy

|

|

Limits

0c

to 40c

|

Limits

-40c

to 0c

+40c

to 85c

|

|

I

peak, Amps

|

3.6

- 4.4 A

|

3.2

- 4.8 A

|

|

I

hold, Amps

|

0.9

- 1.1 A

|

0.8

- 1.2 A

|

|

Current

Leakage at 16 VDC is less than 500 uamp.

Notes:

-

The current profile shown is for an injector

pulse width greater than 5.7msec.

-

Accuracies at 0 C to 40c apply to computer

operation from 11 to 16 V.

-

Accuracies at -40c to 85c apply to computer

mode form 4.5V to 16 V and to backup mode from 4.5 to 16 V

-

Turn-off time is a. function of load characteristics.

-

I peak limits are peak detect threshold levels,

actual peak, current measured during normal operation will vary slightly

as a function of load resistance, load inductance, and battery voltage.

Over shoot with typical injector loads can vary between 10 to 120 ma.

Current Performance

Accuracy

|

|

Limits

0c

to 40c

|

Limits

-40c to 0c

+40c

to 85c

|

|

I

peak, Amps

|

2.0

- 4.4 A

|

2.0

- 4.8 A

|

|

I

hold, Amps

|

0.9

- 1.1 A

|

0.8

- 1.2 A

|

Current

Leakage at 16 VDC is less than 500 uamp.

Notes:

-

The current profile shown is for an injector

pulse width greater than 5.7msec.

-

Accuracies at 0 C to 40c apply to computer

operation from 11 to 16 V.

-

Accuracies at -40c to 85c apply to computer

mode form 4.5V to 16 V and to backup mode from 4.5 to 16 V

-

The hold current specification does not apply

when the battery voltage is too low to achieve the 4 Amp peak condition

Fault Detection

The computer has access to detect a fault

condition by monitoring the injector driver output lead. Detectable fault

conditions include:

-

shorted injector solenoid or output

shorted to battery,

-

An open lead to the injector solenoid.

Injector output fault protection under hardware

control is provided to protect the PCM as a design feature and not intended

to be functionally tested due to possible electrical stress of the PCM.

Under a shorted load condition, or a short

to battery, the driver will limit the load current to the 1 Amp hold value.

The detection scheme functions on the time interval between driver turn

on and the detection of the 4 Amp peak, which is legs than the time interval

of a normal load due to the loss of injector inductance. If

the 4 Amp peak is detected in less than 40 usec as set by PM1D CLK2 timer,

a INJxFLT/ (x = 1 or 2) signal is sent to processor. Subsequent

fuel commands will enable the driver, and if the short is not removed result

in 1 Amp lead currents after the 4 Amp peak is exceeded, as described above.

The processor must clear the fault latch within the PMID via the internal

signal N/cut during the injector off time. An

open injector, or open lead to the injector, is sensed during the off time

of the injector driver by monitoring the output voltage. The PNID, INJxFLT*

(x = I or 2) signal is latched low, and sent to the processor, if the sampled

voltage is less than 0.5 (IGNN +/- 0.5v).

Overvoltage Shutdown

The injector driver and load are protected

by design from excessive currents resulting from over voltage conditions

such as load dump. When internal detection circuitry senses a IGEN voltage

in excess of 30 +/- 5.3 V, the driver is shut off by hardware. Normal injector driver operation will be restored

on the next commanded fuel pulse provided the over voltage condition no

longer exists. Normal functional testing at these voltage levels is not

recommended due to possible electrical over stress of the FET driver.

-

Applies to injector clamping voltage, which

effects injector turn-off time.

-

Pulse width accuracy, which determines injector

on time.

-

Applies during computer injector control over

the battery voltage range of 11 to 16 V and the temperature range of 0c

to 40c.

Typical TBI Loads, Peak and hold mode

The listed loads defined at 25c can

be driven by this PCM

| Injector

type |

Resistance

Oms +6% |

Inductance,

mh

1KHz +/- 15% |

| A |

1.00 |

1.4 |

| B |

1.1 |

1.7 |

| C |

1.26 |

2.7 |

| D |

1.55 |

2.0 |

| E |

1.76 |

2.1 |

|