My Label

Distilling Alcohol!!

My Label

As I have stated before, I am in no way responsible for your actions on making alcohol, for it may be illegal in your area or country and can be hazardous to your health if made improperly. This site is only to show how it can be done for knowledge, and is not intended to try to do it or experiment it. But hypothetically, if you were to try to distill alcohol:

First you would need to have some background knowledge of alcohol and how to make wine. If you do not have any background knowledge of alcohol, click here to go to Making Alcohol Page.

Now, distilling alcohol.

Distilling alcohol is separating the alcohol from the fermented

shit. This can wine, beer, or anything fermented. Some people

ferment corn, this is where moonshine originally came from. You

could also use other grains or potatoes.

After you have the fermented liquid, like wine,

then you have to make a still to evaporate the alcohol and

condence it back into a liquid to collect it. In order to do this

safe you better understand it very well before trying it out. You

have to pay attention to specifics, or you might not make it

safe. If it is not made properly it can make you sick. This is do

to the little amount of methanol in the fermented liquid, and is

why the first part of the alcohol that comes off is to get thrown

away. This is why it is illegal, and not recommended to do unless

you know what you are doing.

The Still

To make alcohol safe the still must be made

properly. It must be made from none poisonous material and have a

accurate thermometer that reads the temperature of the steam

vapor (not the fermented liquid being heated)! The best material

that I recomend to make the still out of would be stainless

steel, or glass; but you could use copper with none lead sodder.

Stainless steel is very hard to weld, believe me, but it can be

done. I tried to use general purpose sodder that said it would

work of stainless steel, but unfortunatly I have had little luck

with it. The still will have to have a proper heating source that

is capable of boiling water and is adjustable. The temperature

the fermented liquid is vaporized is crucial in order to make it

safe. The temperature must be lower than the boiling point of

water but not to low. If the temperature is at the boiling point

of water or over, then the alcohol will not be very strong. And

if the temperature is to low, then it can produce harmful

chemicals! Well, the fermented alcohol will have a small amout of

methanol in it to start with, and it comes off at a lower

temperature, I think about 64 degrees Celsius. But from what I

have read, after that few ml of methanol is already evaporated

and discarded there will be no more of it coming off. Because the

still does not actualy produce the harmfull methanol it just

consentrates it into a harmful amount. Wine, beer, and other

fermented liquids have methanol in it, but is not concentrated

into a harmful amount, it is diluted. The proper temperature

should be about between 70-85 degrees Celsius, or about (156-185

degrees Farinhight), this is the temperature the "body"

ethanol, the good stuff, comes off at. The first 150 ml. is

recommended to get tossed away, to get rid of the concentrated

methanol. From what I have read the recommended lowest

temperature to operate at is 69 degrees Celsius, and I would not

try to go any lower. The time to let the temperature to drop is

when the alcohol coming off gets cloudy, or this may mean that

there is no more alcohol in the batch.

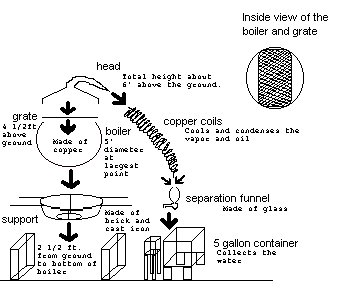

Here is a picture of a still. I

know that you are anxious to see what one looks like.

Click here to a link to a really good detailed paper I

found at someone's web page, on how to make a still as well as

pictures and step by step procedures. Rather than I having to repeat everything that they

state and I might leave out some important information. I believe

that it is a very trustworthy document and would probably cover

more that I could. After you read it all at least twice, come

back here for further advice. If you have any questions,

E-mail me at: [email protected]

Here is another great site on saftey myths about

distilling and much more!

Also, remember there are some things that you

must know to make your own hard liquor. First, throw away the

first 150 ml, because if it is made bad it generally is right

away since it takes a while for the still to warm up. Second, is

that you should strain the alcohol through activated charcoal.

Third, always remember to watch the temperature.

Here is a picture of

a still that I drew.

Okay, after you have read both of them atleast

twice, read below.

Now to make a mash to distill instead of using good wine or beer. The document recommended to use corn, or you can make a neutral mash by just using about 4.5kg of sugar with 20ltrs. of water (about 8lbs. of sugar with 5gal. of water). Then you can add some kind of Turbo Yeast, or you can just add any kind of activated molasses yeast which takes about 2 weeks instead of as little as 4 days as if used Turbo Yeast. When making the mash you don't always have to have a fermentation lock on it as you would with making wine. Or just go to the wine page on this ultimate site.

If you want to see my plans that I have longly

endured you can click here!