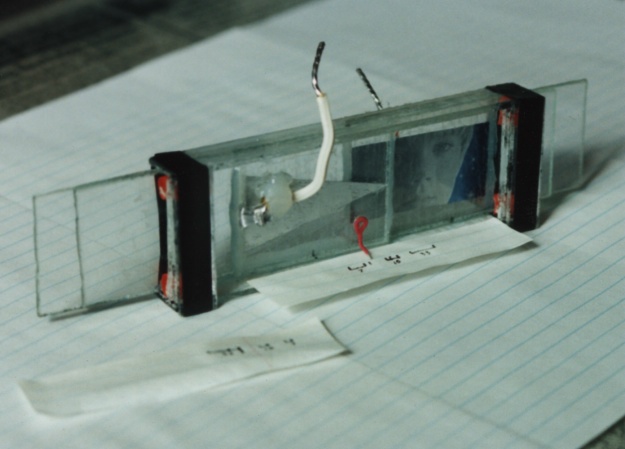

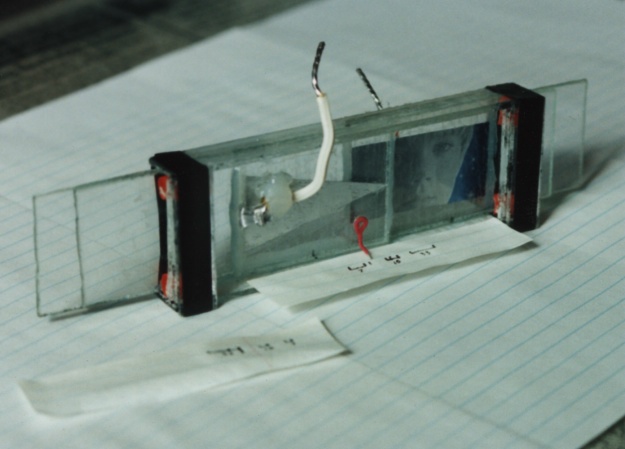

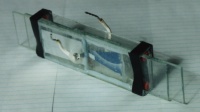

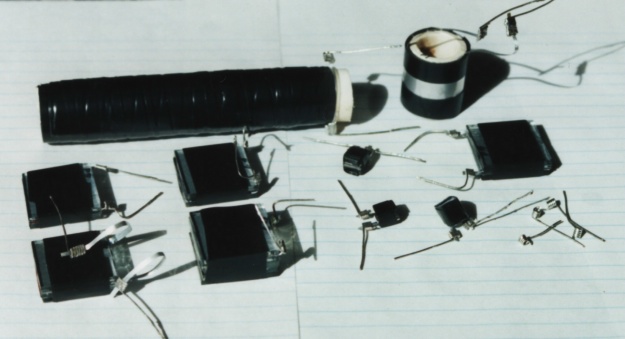

Forms are 1/4" x 1/4" and 1" x 1" glass and � PVC pipe. All are wrapped with electrical tape. Multiple plate legs are combined in crimp connectors and clipped. Spare crimp connector legs are shown in the lower right corner of photo. Plates are made of soda can aluminum. Capacitor media is glass or soda bottle plastic.

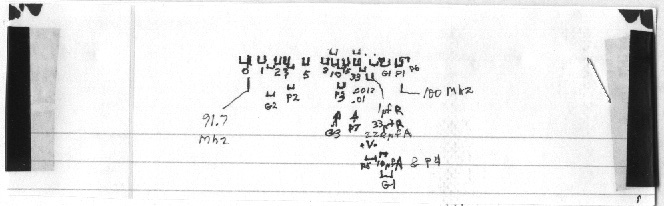

New Radio Dial calibrated in Picofarads with Test Values added

This the ink on paper dial created from calibrated values then used on created capacitors. The 'U' shapes are the upper and lower points where the signal strength light came on. The test station frequency is 91.9 MHZ. With each calibration capacitor connected in parallel to the tuning capacitor of the radio the station tuned in at the marked places higher on the radio dial. The numbers of 0, 1, 2, 3, 5, 8, 10, and 33 pF are in a row. Test capacitors are designated G for glass and P for Plastic soda bottle. G2 and P2 are single plate 1/4 x 1/4 capacitors. Interpreted values are 1.75 pF and 3.4 pF respectively. Directly above P7 is a grouping of electrolytic and disk capacitors. They all have similar values. Disk capacitors are damped for harmonics. The capacitors above the 100 MHZ mark are 1" x 1" and have 4 active media. Connections are made using tiny wire coils wound on 1/16 drill and pre soldered. Use them as crimp connectors. Crush them gently or the aluminum will be cut in half. A single plastic media capacitor wrapped � way around a �' PVC pipe has 4 times the value as the same 1" x 1" media capacitor held flat between glass plates.