Seth Thomas 89

Sessions Clock

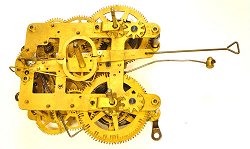

The Seth Thomas 89 mechanism is one of the best mechanisms among the production-grade American clocks of that era, ca. 1920. Since many clock collectors in the United States prefer American clocks over foreign clocks, every collector should consider having a Seth Thomas clock with an 89 series mechanism in his collection.

|

Some of these clocks have stopworks to prevent you from winding the mainsprings too tightly, a terrific feature that every clock should have.

|

If you wind the mainsprings too tightly, or if stronger mainsprings are installed than were originally there, the result could be damage to the gear teeth. Whereas European clocks have mainspring barrels with long teeth for added strength, American clocks with open springs, (no barrel), have short teeth. The result is that all the torque of the mainspring is applied to a very small area of tooth such that, when the mainspring is fully wound, the teeth become compressed as the yield pressure of the metal is exceeded. The other gear in the photo below shows undamaged teeth. The compressed teeth look worn, but you do not see comparable wear on the lantern pinion of the second wheel, so you conclude that compression took place. Close inspection reveals that brass was pushed to the side, and the edges of the teeth are no longer smooth. Thinner mainsprings should be installed on this clock. I recommend 0.0165 inches thick.

|

Below is an example of a screw-in bushing. Some repairmen use them because they can be installed without taking the clock apart. However, if the clock is not taken apart, you cannot polish the pivots. A rough pivot is probably what caused the bushing to wear in the first place. Furthermore, screw-in bushings are ugly and tend to unscrew themselves if not carefully punched in place. This type of bushing is not recommended. If you encounter one at the bench and you find that it has no visible wear and does not tend to unscrew itself, then you may decide to leave it alone in a production-grade clock. Otherwise, replace it with a friction bushing, such as a Bergeon bushing, but a friction bushing of this size will probably have to be custom-made on a lathe. If the clock you are working on is high grade, including Chelsea clocks, Herschede clocks, Elliott clocks, and French clocks, you should consider installing a friction bushing.

|

This clock came in for repair because it would not strike. The lift lever is badly bent out of shape. This kind of damage does not happen by itself, but rather because of improper repairs. The escapement, clearly visible in the next photo, is called a Semi-Deadbeat because the exit pallet acts as a deadbeat but the entry pallet acts as a recoil. If you find one of these clocks with a longer pendulum, such as you would find in a larger wall clock, you would be surprised by how well it keeps time, compared to other production-grade clocks.

|

While the Seth Thomas 89 mechanism is not as easy to work on as the Seth Thomas 30 hour clock shown on this website, both present good learning material for anyone learning how to repair mechanical clocks.

Sessions Clock

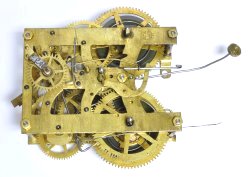

The Sessions clock is another fine example of American manufacturing. Like other American brands, this clock represented an all-American design that reduced the cost of production, especially when compared to European clocks, making these American clocks affordable to more people. While there is no special feature that makes this clock stand out, I feel this clock deserves a special mention. I acquired a Sessions clock in 1993 which was so dirty that you could not tell it was made of brass. Out of curiosity, I wanted to see if it could run, so I lubricated the clock and put it on a test run. To my amazement, it was still running well six months later, so I decided it deserved to be overhauled. Few clocks will run in such condition. The following Sessions was made around 1910.

|

In order to avoid taking the clock apart, someone soldered a Rathburn bushing over a worn bushing. Apart from looking awful, this may have worked if the pivot had been polished. However, to polish the pivot, the entire clock must be disassembled, so you might as well install a friction bushing. Shortcuts are not worthwhile when it comes to bushings and pivots. Any time you see a Rathburn bushing, you should remove it when servicing the clock. The rough pivot was the reason why this clock would not run. In fact, all the pivots in this clock needed to be polished, some more rough than others. This is one of the problems with mass production: lack of attention to detail usually results in imperfectly-polished pivots.

|

The escapement is a Strip-Pallet Recoil Escapement because the pallets are made from a strip of steel, (just like the Seth Thomas 89 above). This clock is a nice piece of American history and every collector should have one.

|

Southern Calendar Clock

Clock Repair Main Page

Escapements in Motion

Links Page

Tributes Page