DESCRIPTION OF MY THESES WORK

IN CHALMERS ROBOTICS LABORATORY.

IMPROVEMENT OF ROBOT INDUSTRIAL STANDARDISATION "IRIS"

Introduction:

The international standard ISO 9283 which concerns the manipulation

of the industrial robots, their performance criteria and their related

test methods, has deficiencies hindering

broad industrial use.

The goals of the project are:

- Inquiry-based investigation of robot test procedures and test equipment

applied at European robot users.

- Determination and analysis of robot-user's requirements for robot

performance criteria, testing procedures and related measurement equipment.

- Classification of different robot test procedures in function of

robot applications, enabling the robot user (particularly SMEs) to select

the right robot for his application.

- Improvement of performance criteria, and related measurement and

evaluation methods/procedures for industrial robots.

Description of the work:

My work consisted mainly on investigation on robots by type of application.

First of all each task must be clearly described including all the variants

and the newest technologies,

showing the weaknesses sides and the advantages of each technological

solution; for instance a passive accommodation using a compliant tool such

an RCC device is a more

suitable choice than an active accommodation using a real time camera

sensor control for robots performing assembly tasks. The choice is done

according to economics and

technical criteria.

A comparison between different technical solutions is done and by the

end a proposal of robots tests is established belonging to the studied

application, for instance the repeatability

test is particularly important for assembly robots, for certain applications

a test with different loads is necessary.

To achieve the investigation, specific books as well as theses were

examined. Internet was also very useful.

The second part of my project (» 4 months duration), after the

IRIS project was fenced, was on Robcadsoftware. The first step consisted

on making myself familiar with the

software and the programming TDL & AML languages through exercises.

I have performed the following exercises :

-On-line programming of ABB IRB2000 robot.

-Off-line programming of IBM 7545 SCARA robot (assembly cell).

-Off-line programming of ABB IRB2000 robot with Robcad, Figure 3 :

Design of existing

gripper, workpieces and cables.

Calibration

of the cell.

Writing a main

program with ARLA using the graphical interface to control ABB robot.

-Writing a connection program with TDL to control the gripper.

-Create a complete simulation.

Collision

detection and TCP tracing.

Downloading

and execution.

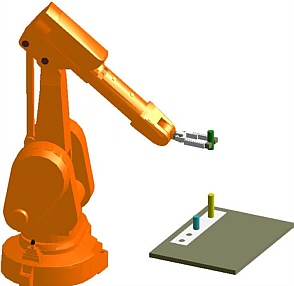

The second step consisted on designing the IBM 7545 assembly cell with

Robcad, Figure 1.

The cell is used to build figures with Lego and Duplo and is part of

a laboratory work for robotics courses. The goal of integrating the cell

to Robcad is to provide students with the

possibility to simulate their programs before the downloading and the

execution. The models will also serve as a basis for further development

and use of the IBM 7547 cell. I

achieved the design as following:

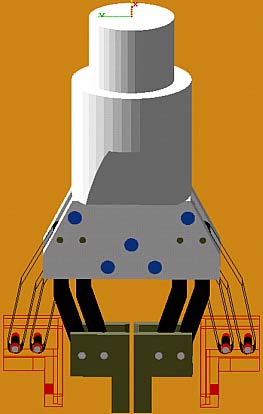

-Designing existing models: grippers (Figure 2), index board, workpieces,

etc...

-Including cinematic, Figure 4, (rotational axis, prismatic links),

defining the ranges of movements.

-Calibrating the whole cell by using locations.

-Programming with AML, main program and subprograms connections (gripper,

index board, vacuum, outputs...).

-Simulating the program, studying the robot accuracy and the collisions.

Robcad is widely used in the automotive industry, giving the advantage

of a full study (cinematic and dynamic) of robotics processes and an easy

off-line simulation of assembly

tasks.

These are some extracts from my experience on Robcad software, Design

and simulation on the ABB and the IBM robot.

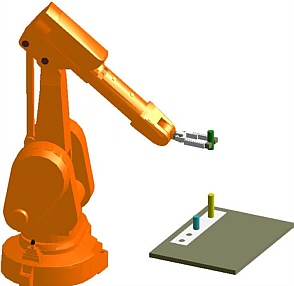

Figure 1: A virtual assembly cell of an existing cell with IBM SCARA

7545 performing figures with Duplo and Lego for a robotic course.

This allow to creat Off-line programs then a simulation with the software

and if every thing is ok a download to the real cell.

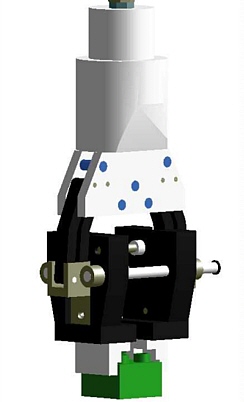

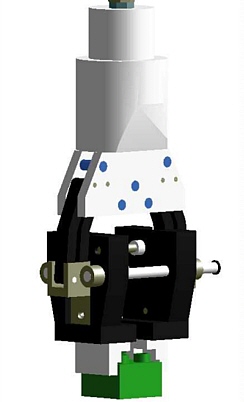

Figure 2: A close-up on the virtual IBM gripper, every details are

included for a closer realistic simulation.

|

Figure 3: Exercise for accuracy test with ABB IRB2000, the cylinders

must be put one on the top of the other, then each one placed back in its

initial place.

|

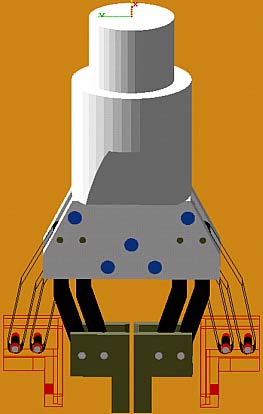

Figure 4: The gripper Cinematic and rotational axis, the fingers contact

surface should always stay in a vertical plan.

Back

to Home