1962 - 413 Cid Mopars

From an engineering standpoint,

Chrysler Corporation's maximum-performance horsepower hardware for

1962 was built into the most advanced new car offerings of all time.

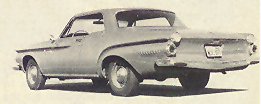

Not only did they package their action in the lightest of all the

full-size vehicles available from the domestic auto makers, but

Chrysler also executed their offerings in the most radical fashion. |

|

And when you consider that the Corporation didn't

even offer a reasonably sized performance car before the '62 model run (their

413 engine had been available in only in the biggest and heaviest Chryslers

in the line), the release of the short-ram 413 wedge engine in Dodges and Plymouths

was truly a forward-looking move.

Built up around better

breathing for their biggest incher, the 413 engine block itself

received little special attention outside of main-cap hardness checks

and unique valve unshrouding notches cut into the top of each cylinder's

bore. Crankshaft, connecting rod and piston forgings were of the

highest grade available, while the long-duration solid-lifter camshaft

and the adjustable rocker train were already-proven pieces borrowed

from the well-tested Chrysler 300 letter-series line. The biggest

performance improvers, however, involved new cylinder head and manifolding

designs intended to move the maximum amount of air through a motor

in a given unit of time. |

|

The all-new race-oriented max-wedge heads had

25-percent-larger ports, a full 1/8-inch-bigger exhaust valves, reshaped intake

valves, stiffer dual valve springs, no heat passage to the intake manifold and

restructured deck surfaces for added clamping rigidity. Stainless steel head

gaskets were also included for improved head-to-deck sealing, forged 13.5:1

pistons, shot-peened rods, hard copper/lead main and rod bearings, high-volume

oil pump, baffled oil pan, and a completely new valve train with a solid-lifter,

300° camshaft. The only trouble with the dual valve springs was that valve-stem

seals wouldn't fit.

This resulted in '62 413s suffering from excessive oil consumption�as much as

a quart every 50 - 100 miles. Still, the owner's manual said the engine was

safe to 6500 rpm�but for sustained bursts not longer than 15 seconds.

To top things off, the

factory engineers developed a one-piece alloy intake manifold designed

to use air flow pulses to help fill the cylinders. The intake was

the unique short cross-ram Chrysler's cross-ram featured 15-in.-long

manifolds criss-crossing over the engine and big Carter AFB 4-barrels

mounted on integral plenum chambers above each valve cover. |

|

The layout was a natural evolution of the long-ram manifolds

Chrysler had used in the '60-'61 period. The internal runners' capacity, the

size and shape of the dual undercarb plenums and the location of the carbs on

the plenums were all resolved in a single compact casting specifically intended

to feed the '62 413's high-flow cylinder heads. Assists in the inlet system

were also provided by a multi-valved high-pressure fuel pump and by unsilenced,

low-restriction air cleaners for the twin Carter AFB carbs. The new cross-ram

aluminum manifolds were good for an extra 10-15 HP.

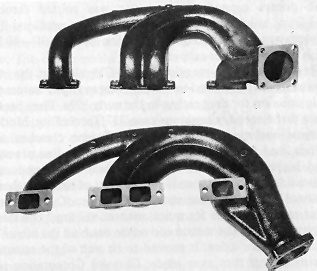

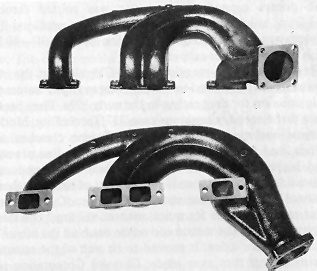

The all-new upswept exhaust manifolds were also

quite exotic in appearance. Huge iron castings looped up over the fenderwells

to carry individual passages back to big 3-in. headpipes and all indications

were that the large-capacity tuned castings were every bit as effective as they

looked.

Huge iron castings

looped up over the fenderwells to carry individual passages back

to big 3-in. headpipes. There truly was nothing else like them in

the industry.

|

|

Breathing efficiency was further enhanced by

what, to this day, amounts to the most complete street and strip exhaust system

ever installed on any assembly-line automobile. The headpipes were designed

with dump tubes that could be quickly uncapped for street or strip racing. a

balance tube connecting the headpipes helped to quiet down and to tune up the

waste flow. Backed by dualhigh-capacity New Yorker mufflers, the system efficiently

terminated in full-length, 2-inch tail-pipes. The system was so efficient that

the engine lost only 30�40 HP with the dump tubes capped!

The headpipes were designed

with dump tubes that could be quickly uncapped for street or strip

racing. a balance tube connecting the headpipes helped to quiet

down and to tune up the waste flow. |

|

There were two horsepower versions of the 1962- 413 cubic

inch engines.

One with 11.0 to 1 compression ratio rated

at 410 Hp @ 5400 rpm. and the

other a whopping 13.5 to 1 rated at 420 Hp

@ 5400 rpm.

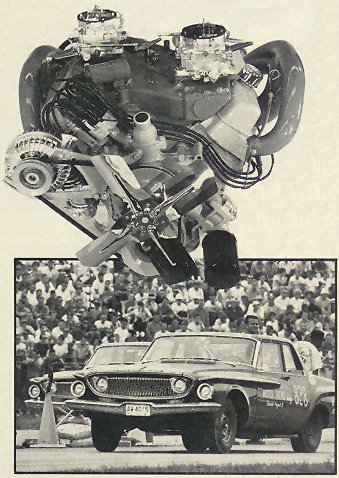

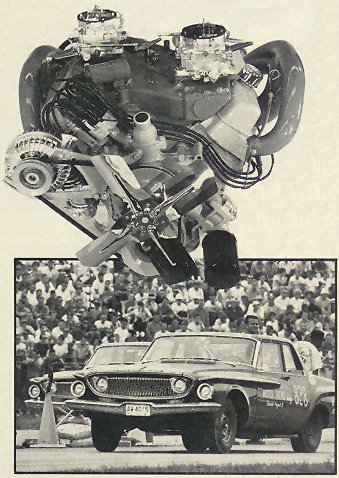

The 413-engined "Ramcharger"

Dodge and "Super Stock" Plymouth packages also included

extra-duty running gear and standard-style high-performance support

equipment for all (suspension, fuel, cooling, electrical and lubrication)

on-board systems. |

|

How Fast Were They ???

Reported performances include a showroom-stock

clocking of 14.4 at 101 mph for a 3440-pound, 3.91:1-geared, street-tired Dodge

that was also equipped with an optional automatic transmission. Chrysler's three-speed Torqueflite was the only non-standard-shift

factory trans ever fitted to an assembly-line super stocker, and what's more,

gear changes with this unit were made by simply pushing a button! Using a pair

of sticky Atlas Bucron tires, this same car, running with the exhaust cutouts

open, clocked a 13.44 quarter at 109.76 mph. A 4.56:1-geared manual trans version

of the 413 Dodge used basic strip tuning, tubing headers and 7-inch-wide M&H

race tires to record a quarter-mile test best of 12.97 at almost 114 mph.

The 413's performances regularly put it into the winners' circles in both straightaway

and speedway action.

Copyright © 1999 Bruce Cresswell