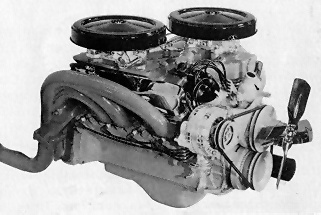

In 1963, Chrysler unveiled its Stage II racing package. It was a step forward in almost every area of

the car. Bore was increased 1/16 in., upping displacement to 426 cubes. Breathing was improved

with larger carbs, recontoured intake ports, machined reliefs in the combustion chambers around the

valves, and a new camshaft with more duration and lift. Reliability at 6500 rpm was aided by adding

material to the connecting rods around the bolts. Main-bearing grooving was increased threefold to

increase oil flow to the rod bearings. And new valve-stem seals were Fitted, remedying the excessive

oil-consumption problem. The 426-II engines were 30-40-HP stronger than the '62 413s.

Improved durability was especially appreciated on the NASCAR tracks.

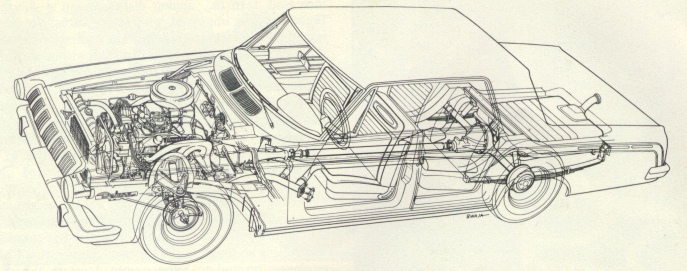

The big story on the Stage-II body was the weight-cutting program. The unit-body Dodge and Plymouth coupes were the lightest full-size cars in the industry. But competition was getting so tough in the top-stock classes that Chrysler engineers wanted to bring weight down to the allowed 3200-lb minimum.

I have heard tales that to homologate the 63 Dodges for NASCAR they had to sell a minimum number of cars (lightweight), people that had ordered max-wedge cars may have originally recived the cars with standard steel front ends. To make up the numbers Dodge sent aluminium guards and assorted lightweight parts to the owners for them to fit if they wanted. ( does this mean there are brand new aluminium bits lying around in garages that have never been fitted to a car before ??)

This was good enough for the NASCAR rulemakers and allowed the 1963 Dodges to compete in the NASCAR races that year.

All it took was an aluminum hood, inner and outer fender panels, radiator and bumper brackets. A secondary advantage of the new hood was that it gave an opportunity to design an air scoop to feed cooler, denser, outside air to the carbs. This scoop was said to add 2-3 mph to the trap speed. |

|

It should also be mentioned that Chrysler was the only company that bothered to develop a heavy-duty automatic transmission for drag racing in the early '60s. They beefed up a three-speed, aluminum-case 727 Torqueflite. Modifications included: high-friction-coefficient clutches and bands, and recalibrated hydraulics for more line pressure and higher shift points. The result was a stab-and-steer drive line that was not only quicker out of the hole than a manual four-speed, but virtually bulletproof. Pushbutton gear selection made for quick manual shifting. The cushioning effect of the torque converter doubled the life of U-joints and rear axles. It proved to be one of the smartest racing moves they ever made. Chrysler Corporation cars cleaned up in all the top Stock/Automatic classes for years.

Click here to see a Brochure put out

by Dodge on the 1963 Ramchargers

|

|

Copyright � 1999 Bruce Cresswell