Created: 18-JUL-99

Last Updated: 18-JUL-99

Created: 18-JUL-99

Last Updated: 18-JUL-99

|

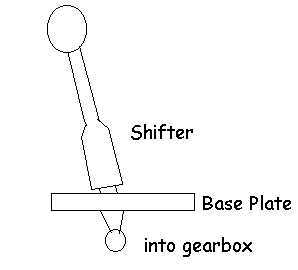

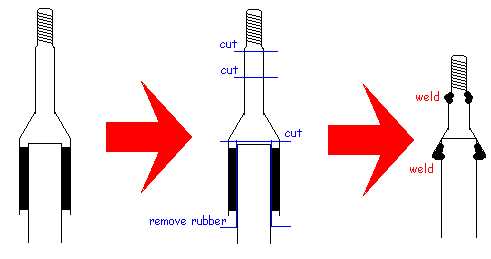

Firstly, there are two steps taken here - one is how to make a short shifter - basically a cut-down stick, the other is making a quick shifter - changing the pivot point of the shifter for a quicker ratio. SHORT SHIFT My T18 shifter was over 10 inches long from factory so it was just ridiculous and took a month to change gears. So I decided it needed a little attention :) First step is to find a spare gear shifter assembly just in case you make a mistake or dont like the result - I grabbed one from Pick-a-Part - I found in the TE72 the base of the shifter doesnt come apart from the stick part - so I had to unbolt the whole assembly. Below is a _very_ quick sketch of a shifter assembly which I started off with.  Ok, then I got busy with multigrips and a bench clamp trying to remove the upper half of the shifter from the rubber surround holding it into the lower half - but alas the damn thing REFUSED to come out.. I tried everything from hot knives to brute force - in the end i set fire to the bottom part of the shifter and melted the rubber out as much as I could - then took to it with a blade, and then while it was hot i went back to the multigrips and bench clamp - eventually got the upper and lower half apart. Next I cut the thread from where the gear knob fits and set that aside. Then I hacked about 4 inches off the main gear shifter extension piece - and about 2 inches off the rubber surround section - making sure I kept the flange section in one piece so as to make welding a little easier. Next I welded the three sections together to make the shorter shifter. See below diagram for an idea what I am babbling about:

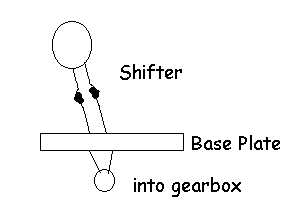

The reason I removed the rubber surround is so I got a more direct feeling with the gearbox - thought it can really send a shock up your arm if you crunch gears. Then all I did was remove the old shifter assembly from the gearbox, bolt this one in and I had a short shifter! OK, well I went a tad overboard with my cutting and wound up with a 4" gearstick (see the photo at the bottom of the page) - a little too short, but hell it made shifting bloody quick, and the T50s are so easy to change gears anyway that removing most of the leverage wasnt a real problem.

I would recommend only cutting it and leave at least 5-6" of shifter otherwise you have to lean forward to reach the gearknob.. Damn, i got a sore back :( As you can see from the below picture, My shifter was very short, and I used a gearknob from a Series 3 corolla.

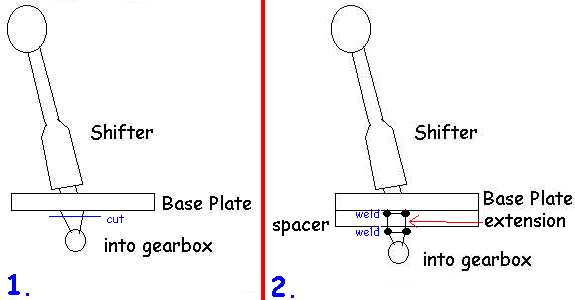

QUICK SHIFTER OK, this is a very simple addition to the above shifter modification. Basically, all you are doing is moving the pivot point so as to get the shifter throws shorter without cutting the size of the shifter down. Simple leverage principals.. Only drawback is that the shifter is a little harder to move - not really a concern seeing as most car gearboxes are resonably easy to move anyway. See the below diagram for an idea of what im talking about.

As you can see from the picture, the lever inside the gearbox is cut and an extension piece is added. Next make a spacer which replicates the original base plate - this should be the same thickness as the extension piece is long - otherwise the lower part of the lever will not line up inside the gearbox correctly. Also be sure that the welds are of a good standard otherwise if they break off inside the box, you are asking for trouble. Dont forget you will need longer bolts into the box now to accomodate the spacer. |

| Top | Main Cars Page |