Created: 17-JUL-99

Last Updated: 17-JUL-99

Created: 17-JUL-99

Last Updated: 17-JUL-99

|

> What do they do to a standard fuel tank to make it EFI compatible? And > exactly what is a "swirl pot" or "surge tank"?? |

|

|

(reply from [email protected]) The big difference with EFI vs CARB is that the EFI requires the fuel to be under constant high pressure. If the pump pulls air for even an instant, the pressure will fall, and it will go lean. This is instant. With a carb, it can run off of the fuel bowl for a while before the mixture changes too much. Most factory systems have the fuel pump in or at the fuel tank. The line to the fuel rail all the way to the regulator is under pressure. From the regulator there is a return line back to the tank for the fuel the engine does not use. this line is not under pressure, and should go to the bottom of the tank. The tank will also have a vent line, usually to a charcoal canister. If you wish to use a carb fuel tank, there are a few options. The simplest is to have a carb type fuel pump feed into a small tank in the front of the car. Then this tank can have the high pressure fuel pump for the injection in it, and accept the return line. This is what is sometimes called a surge tank, or swirl pot. If you use the carb pump to feed this tank, you either need a float with needle and seat, or a sealed pot that will run under the pump pressure, say 4 psi for a typical carb setup. You have to be careful about trapping air in that type setup though. |

|

|

(reply from "Simon Fock" [email protected]) In a carby motor you have a small reserve of fuel siiting in the carby bowl. An EFI motor relies on very high fuel pressure behind the injector (around 50psi compared to about 2-3psi which feeds your carby - oh yeh you also need to make sure you run proper fuel injection hose - or better - as standard carby fuel line is only rated to around 10psi). EFI systems also pump very high volumes, which is why you MUST RUN A FUEL RETURN LINE BACK TO THE FUEL TANK. The pressure in the fuel rail is controlled by a regulator which bleeds off the excess fuel back to the tank via the return line. When the pumps pickup runs dry, because it is high volume, it runs dry almost instantly - leading to low or no fuel pressure and possible lean mixtures and terminal engine failure, or at least the engine stalling. This is why you need a surge tank or swirl pot. The pot can either be a vertical tube welded to the bottom of your existing tank (but get someone who knows what they are doing as I would expect an exploding fuel tank would hurt quite a lot) or can be a separate tank (once again a vertical tube) with a separate feed pump. The feeder pump should have a higher volume of flow than the pressure pump, when the injectors are going flat out (or the return line feed into the surge tank - although this causes heat build up problems) otherwise your surge tank will run dry and you'll get the same disastrous scenario I mentioned above. The surge tank should also have an overflow line back to the main tank. |

|

|

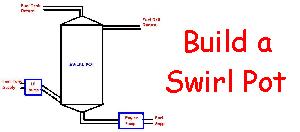

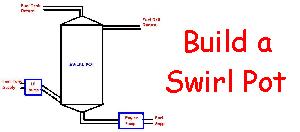

HOW TO BUILD A SWIRLPOT: This is a modified instructional e-mail from Bill Sherwood has been used as the basis of the below text and pictures. I computerised Bills hand-drawn pics. No use me rewriting all this really.. In the picture 'swirl2.jpg', I've drawn up a schematic of how to do an EFI system properly. As you can see, you need two fuel pumps. The first one doesn't have to be a high pressure one like the normal EFI pump, it can be a 'normal' high *volume* pump, as used in carby-fed V-8's. All it does is keep the swirl pot full, and doesn't pressurise the fuel rail at all. The second pump is the usual high pressure pump for the EFI system - That side of things is unchanged. Basically, you treat the swirl pot as a 'mini' fuel tank as far as the EFI system is concerned, and the low pressure pump just keeps it topped up.

swirl2.jpg Ok, the design of the swirl pot is important, and not many people do it right. Look at the 'pot.jpg' picture, and you see that I've (crudely!) drawn a diagram of where the pipes go. If you do it like this, then you'll be able to get every last little bit of fuel from the tank, and also not have hot fuel returning from the fuel rail immediately going back into the engine.

swirlpot.jpg Ok, the design of the swirl pot is important, and not many people do it right. Look at the 'swirl2.jpg' picture, and you see that I've (crudely!) drawn a diagram of where the pipes go. If you do it like this, then you'll be able to get every last little bit of fuel from the tank, and also not have hot fuel returning from the fuel rail immediately going back into the engine. For my Sprinter, I plan on having the pot being about 2 litres in capacity. I've got a chunk of 5" diameter alloy pipe, so that will make it about 15cm tall. (I have a reason for this ...) On the bottom of the pot, you have two lines - One coming from the LP (low pressure) pump and the other going to the HP (high pressure) pump. The one coming from the LP pump should come in on the side of the pot down low, thus causing a swirling action. (Hence the name of the swirl pot ... ;) ) The swirl action is important, as you'll see shortly. The line out, to the HP pump can come out either the bottom of the pot, or via a pipe that comes in from the side. It doesn't matter. It also doesn't *really* matter where the pick-up point is, but I think it's best over near the side so it stands the best chance of getting fuel all the time. That's with a flat bottom to the pot - If you have a tapered bottom, (As the diagram shows) then you must have the pick-up in the centre. Ok, up the top end there's another two pipes. The easy one is the return line TO the fuel tank - It MUST be in the centre of the pot. The reason for this is because the fuel is doing it's 'swirl' thing, and so any air that gets into the pot will be pushed towards the centre of the top of the pot. Since that's where the return line is, the air will disappear *very* quickly. The return line from the fuel rail is like the LP pump's line, but on the opposite side normally. The reasons for this is because the fuel is coming Out of the fuel rail at a great rate, so it helps the swirl action a fair bit. Now, the reason that this system works is because it keeps the hot fuel up the top of the pot and the cool fuel from the tank at the bottom. Air won't last long in the pot either. The other thing that I'm probably going to be doing is to have a 2psi pressure switch in the LP pump line to the pot - What that's for is so I can tell when I'm running low on fuel. (The fuel level gauges in most cars are notoriously inaccurate!) The switch will have a light on the dashboard attached to it, and when it starts to flicker I know I'm getting low on fuel. When it comes on for good, I know that I've got just under 2 litres of fuel definitely left (the capacity of the pot) and since I know that the car will do at least 10km per litre, I've got no more than about 15kms to find a petrol station ... ;) |

| Top | Main Tech Page |